In the intricate dance of fluid dynamics, how do we ensure the seamless regulation and control of flow, the very lifeblood of countless systems? Its a question answered by the critical selection between ball valves and gate valves, a choice that can make or break the efficiency and longevity of any plumbing or industrial undertaking.

Valves are the unsung heroes of modern engineering, working tirelessly behind the scenes to manage the flow of everything from water and gas to more complex media within pipelines and systems across a multitude of industries. The choices, however, can be overwhelming. The ideal valve selection is crucial to guarantee the smooth operation and longevity of these essential systems. Making the right decision means understanding the distinct advantages, disadvantages, and specific applications of each valve type.

This piece aims to offer clarity, guiding you through the complexities of ball and gate valves, empowering you to make informed decisions for your specific requirements. We'll dive deep into their structural characteristics, operational differences, and suitability across a wide array of scenarios.

- %D1%8D%D0%BC%D0%B8 %D0%B4%D1%83%D0%BD%D0%BA%D0%B0%D0%BD

- Dark Girl Names

- The Bible Verse About Tattoos

- Marriott Hutchinson Island

- Scarlett Estevez Height

| Category | Details |

|---|---|

| Valves: Overview | Essential components used in various industries for controlling fluid flow. |

| Ball Valves: Primary Function | Rapid on/off action, excellent sealing. Ideal for frequent operation. |

| Gate Valves: Primary Function | Suited for systems that require valves to remain open or closed for extended durations. |

| Key Differences: Operating Mechanism | Ball valves utilize a rotating ball with a through-hole for flow control, whereas gate valves use a gate that slides in or out to manage flow. |

| Structural Design | Ball valves: Simple design, featuring a ball with a hole. Gate valves: More complex, employing a gate that moves perpendicular to the flow. |

| Ideal Applications | Ball valves: Best for applications requiring quick shut-off and reliable sealing. Gate valves: Ideal for situations where the valve must stay open or closed for long periods. |

| Advantages & Disadvantages | Ball valves: Easy to operate and offer excellent sealing. Gate valves: Can handle high-pressure and large pipe sizes but may be unsuitable for quick operation. |

| Maintenance Requirements | Ball valves: Typically require less maintenance. Gate valves: May need more frequent maintenance, particularly for the gate and stem packing. |

| Cost Considerations | Ball valves: Generally more cost-effective for smaller pipe sizes. Gate valves: Can be more economical for larger sizes and full-bore flow. |

| Selection Factors | Consider pipe size, system pressure, fluid type and temperature, operational frequency, space constraints, and cost when choosing. |

| Longevity & Durability | Both valve types are durable. Ball valves: Often made of durable materials like stainless steel or brass. Gate valves: Require regular maintenance for longevity. |

| Standards & Certifications | Valves should meet industry standards, such as ASME B16.34, API 6D, and ISO 14313, to ensure quality and performance. |

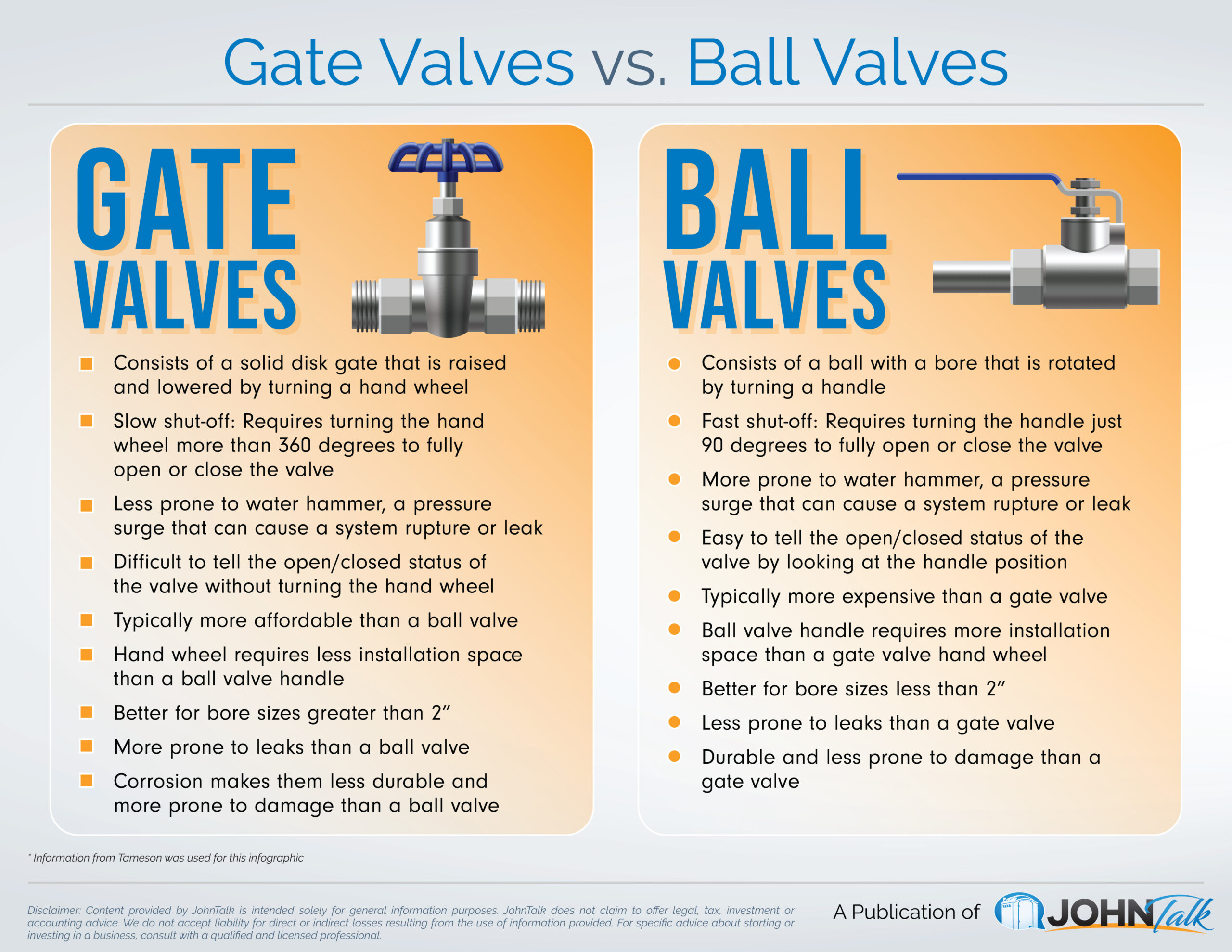

Ball and gate valves represent two of the most widely utilized valve types across diverse industries. While both are designed for the fundamental task of controlling fluid flow, their operating mechanisms and ideal applications diverge significantly. A ball valve, in essence, employs a rotating ball with a precisely drilled hole to manage the flow path, acting as a quick-acting on/off switch. In contrast, a gate valve uses a sliding gate or wedge that moves perpendicular to the flow, either opening or closing the passage entirely.

Ball valves, known for their speed and efficiency, are particularly suited for applications demanding frequent operation and reliable sealing. They excel in scenarios where a swift and decisive shut-off is paramount. This design makes them ideal for systems that benefit from quick transitions between open and closed states. Gate valves, on the other hand, are optimized for applications where the valve must remain in a single position either fully open or fully closed for extended periods. These valves provide a clear, unobstructed flow path when open, with minimal resistance.

A thorough understanding of the fundamental differences between these two valve types is essential for anyone involved in selecting the right valve for a project, ensuring that the selected valve type aligns perfectly with the specific demands of the system. Let's examine the structural differences in detail.

- Jordan Mcgraw Ex Wife

- Miracle Watts P Valley

- Jordin Sparks Love Will

- Tom Jones Son

- Laverne Cox Original Name

The structural design of a valve directly determines its functionality and performance characteristics. The differences in the internal structure and mechanism are the key factor that sets them apart.

Ball Valve Structure

The core of a ball valve is a spherical disc containing a port or hole at its center. This ball rotates within the valve body, accurately aligning the hole with the inlet and outlet ports to either permit or block the flow of fluid. This simple yet effective design enables quick shut-off capabilities, with the ball rotating a mere 90 degrees to transition between fully open and fully closed positions. Ball valves are primarily categorized into two main variants:

- Floating Ball Valve: The ball in this design is supported by the upstream pressure, allowing it to move slightly within the valve body. This movement ensures a tight seal against the seat when the valve is closed.

- Trunnion-Mounted Ball Valve: In this design, the ball is securely fixed in place with a trunnion, significantly improving stability and reducing wear and tear, especially under high-pressure conditions.

Gate Valve Structure

Gate valves control flow by either raising or lowering a gate, or a wedge-shaped disc, to manage the flow path. The gate is connected to a stem, which moves up or down as the handwheel is turned. This straightforward mechanism provides a linear motion, with the gate either fully inserted into the flow path to block it or fully retracted to open the passage. Gate valves are available in two primary designs:

- Rising Stem Gate Valve: In this type, the stem rises above the valve body, providing a clear visual indication of the valve's position. This visual confirmation simplifies operational monitoring and is especially useful in situations where the valve is not easily accessible.

- Non-Rising Stem Gate Valve: The stem of this valve remains within the valve body, making it ideal for applications with limited space or where the exposed stem could be vulnerable.

The choice between a ball valve and a gate valve is primarily driven by the specific application requirements. Each valve type is designed with unique characteristics, optimizing its performance in particular scenarios.

Ball Valve Applications

Ball valves are a premier choice for applications requiring swift shut-off capabilities and dependable sealing. They are often employed in scenarios that benefit from quick operational transitions and efficient fluid control. Common uses include:

- Pipeline systems for water, gas, and oil: Ball valves provide effective control over these essential fluids, ensuring safety and operational efficiency.

- Chemical and petrochemical industries: Their robust design makes them suitable for handling a range of corrosive and high-pressure substances.

- Fire protection systems: Ball valves are crucial for rapidly shutting off or opening water lines in emergency situations.

- Residential plumbing systems: Their ease of use and reliable sealing make them a standard component in homes.

Gate Valve Applications

Gate valves excel in applications where the valve must remain either fully open or fully closed for prolonged periods. They are designed for systems that prioritize full-bore flow and minimal pressure drop. Typical applications include:

- Water treatment plants: Used to control the flow of water through various stages of treatment and distribution.

- Power generation facilities: Gate valves manage the flow of steam and other fluids in these complex systems.

- Pipeline systems for large-scale industrial applications: They are ideal for large industrial applications that require full flow.

- Steam systems: Their design allows for the effective management of steam flow.

When comparing the performance of ball valves and gate valves, several factors must be considered, including their ability to control flow, their pressure ratings, and their resistance to high temperatures.

Ball valves are lauded for their outstanding sealing characteristics, making them suitable for high-pressure and high-temperature applications. They are also notably easier to operate, typically requiring less torque to open or close. However, they may not be the optimal choice for throttling applications, where the valve is partially open to control flow, due to the potential for wear on the ball and its seat.

Gate valves, on the other hand, are optimized for applications that demand full-bore flow. They excel in systems where minimal pressure drop is essential, and they are suitable for larger pipe sizes. However, they are generally not recommended for frequent operation because repeated use can lead to wear on the gate and seat over time. Their design focuses on maximizing flow when open and providing a secure seal when closed, making them best suited for situations where the valve is not frequently adjusted.

Regular maintenance is essential for maximizing the longevity and performance of both ball valves and gate valves. Consistent upkeep ensures that these critical components continue to operate efficiently and reliably over their lifespan.

Ball valves are often preferred for their simple design and fewer moving parts, resulting in relatively low maintenance requirements. However, they do benefit from periodic maintenance, including lubrication and regular inspection of the ball and seat for any signs of wear or damage. Regular inspections ensure that the valve maintains its sealing integrity and operational efficiency.

Gate valves, with their more complex mechanisms, often require more frequent maintenance to ensure optimal performance. Its essential to inspect the gate and seat regularly for signs of corrosion or damage, which can compromise the valve's sealing capability. Additionally, the stem packing, which prevents leaks around the stem, should be replaced as needed to maintain the valve's integrity. Proper maintenance minimizes the risk of system failures.

The cost implications of choosing ball valves or gate valves can vary widely, and is largely determined by the size of the valve, the materials used in its construction, and the specific requirements of the application. Understanding these cost variations is crucial for effective budget planning.

Ball valves often prove to be more cost-effective, particularly in smaller pipe sizes and applications where rapid shut-off capabilities are essential. Their design and operational simplicity contribute to lower initial costs and reduced long-term maintenance expenses, making them an economical choice in numerous scenarios. Gate valves, while potentially more expensive upfront, might be a more economical choice for larger pipe sizes and for applications where unimpeded, full-bore flow is a priority.

When evaluating costs, it is crucial to consider not only the initial purchase price but also the long-term implications of maintenance and replacement expenses. Ball valves, known for their extended lifespan and reduced maintenance needs, can offer superior value over time, offsetting their initial costs through lower operational expenses and reduced downtime. Strategic cost analysis that encompasses both upfront and long-term costs is critical for making sound investment decisions.

Selecting the correct valve for a given application involves a multi-faceted evaluation that considers several critical factors, as this ensures the efficient, reliable, and safe operation of the entire system.

- Pipe size and system pressure: The physical dimensions of the piping system and the pressure levels within it dictate the size, material, and pressure rating of the valve needed.

- Fluid type and temperature: The nature of the fluid being handled, including its chemical composition and operating temperature, influences the choice of valve material to prevent corrosion or degradation.

- Frequency of operation: How often the valve is opened and closed impacts the choice, with some valves being more suitable for frequent use than others.

- Space constraints: The available space in the system's layout can limit valve size and design, necessitating a careful selection.

- Cost and budget considerations: Balancing the initial investment with long-term maintenance and replacement costs is essential for making informed financial decisions.

For example, in residential plumbing, a ball valve is often the preferred choice due to ease of use, reliability, and cost-effectiveness. It provides quick shut-off and a reliable seal, making it ideal for home applications. On the other hand, a gate valve may be better suited for large-scale industrial applications, especially where unimpeded, full-bore flow is essential. The choice is crucial for ensuring the system's proper functionality.

The longevity of a valve is a direct result of the materials from which it is made, its underlying design, and the operating conditions it is subjected to. The materials used in a valve significantly impact its durability and resistance to wear, corrosion, and other environmental factors.

Ball valves, for example, are commonly crafted from durable materials like stainless steel, brass, and PVC, which are known for their robustness and resistance to corrosion. With proper maintenance and operational care, these valves can last for decades, maintaining reliable performance over the long term. Gate valves, while also designed for durability, can experience wear and tear over time due to their more complex design. Regular maintenance and inspection are essential for ensuring that these valves continue to function efficiently and effectively throughout their lifespan.

The selection of a valve must be based not only on performance and functionality but also on compliance with industry standards and certifications, as this assures the user of the valve's safety, quality, and suitability for its intended application.

Both ball valves and gate valves are subject to rigorous testing and certification processes to ensure they meet predefined performance, safety, and quality standards. These certifications are often issued by recognized bodies, such as ASME (American Society of Mechanical Engineers), API (American Petroleum Institute), and ISO (International Organization for Standardization).

- ASME B16.34: This standard outlines the requirements for pressure-containing shutoff valves, ensuring that the valves are designed and manufactured to withstand specific pressure and temperature conditions.

- API 6D: Specifically focused on pipeline and pipeline-related equipment, this standard provides guidelines for the design, manufacture, testing, and operation of valves used in oil and gas pipelines.

- ISO 14313: This standard, from the petroleum and natural gas industries, specifies requirements for the design, manufacture, and testing of ball valves.

Valves that have been certified to these standards have undergone rigorous testing, ensuring that they meet performance, safety, and quality requirements. It is essential to verify the certifications of the valves being purchased to guarantee that they are appropriate for the specific needs of your application. Compliance with these standards underscores the quality, reliability, and long-term performance of the valve.

- Lorne Michaels Net Worth

- Good Nickname

- Tobias Actor

- Loredana Deutschland Sucht Den Superstar

- %E3%82%AF%E3%83%A9%E3%82%A4%E3%83%B3 %E3%82%B3%E3%83%8B%E3%83%BC